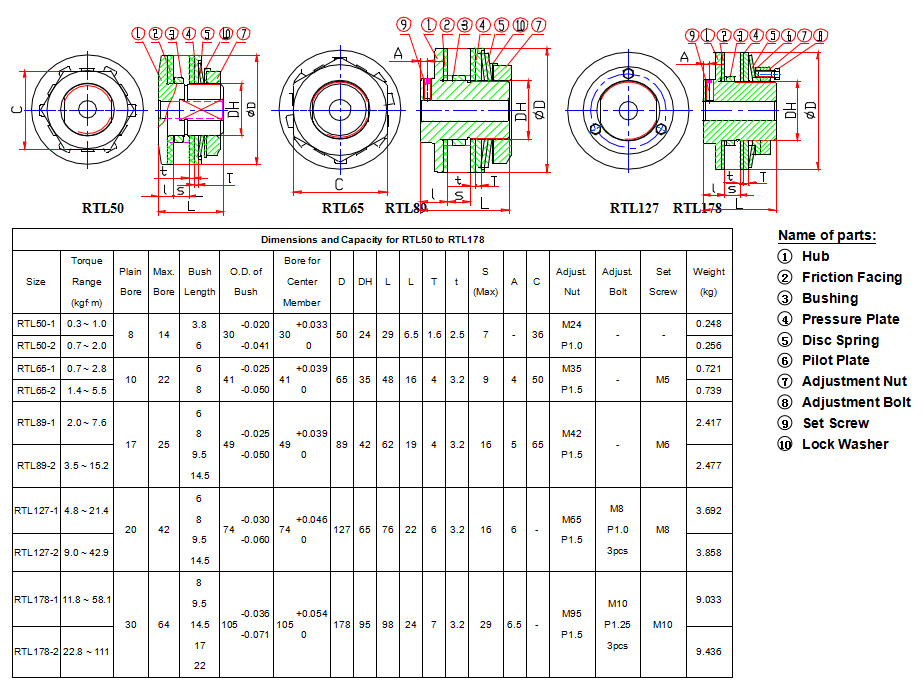

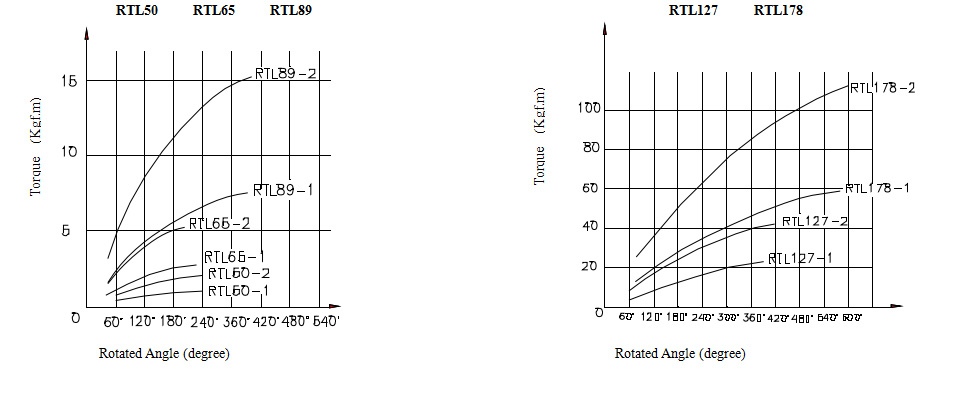

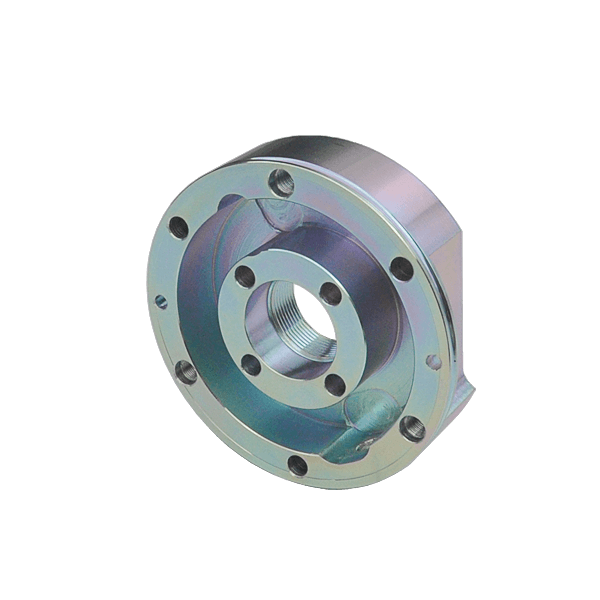

Torque setting of the torque limiter is achieved by tightening or loosening the adjustment bolts and/or the adjustment nut. For torque adjustment of RTL50 through RTL89, an adjustment nut is provided, and for RTL127 through RTL178, adjustment bolts are provided. The torque setting can be made after mounting the torque limiter on the shaft. The process is: For RTL50 through RTL89, First, rotate the adjustment nut tightly by hand so that the disk spring fits the plate. Then tentatively tighten the nut by about 60 degrees with a wrench. | For RTL127 through RTL178, First, rotate the nut for fixing the disk spring to the plate, and then tighten each adjustment bolt by about 60 degrees. Then, if the torque limiter slips under normal loading conditions, tighten the nut (for RTL50 ~ RTL89) or the bolts (for RTL127 ~ RTL178) gradually until the torque limiter stops slipping. Always tighten (or loosen) the bolts equally. Try this adjustment several times to find the proper torque setting for the machine. For your guidance, the below chart shows the relation between the effective rotated angle and preset torque. For precise torque setting, run-in of the torque limiter is recommended, for example, 500 revolution at 50 ~ 60 rpm with a rotated angle of 45 degrees |